Lorem

Since our foundation in 2006, Unison has grown from a small team of experts with a passion for processing solutions, to a leading manufacturer and developer of innovative liquid processing equipment, parts and machinery.

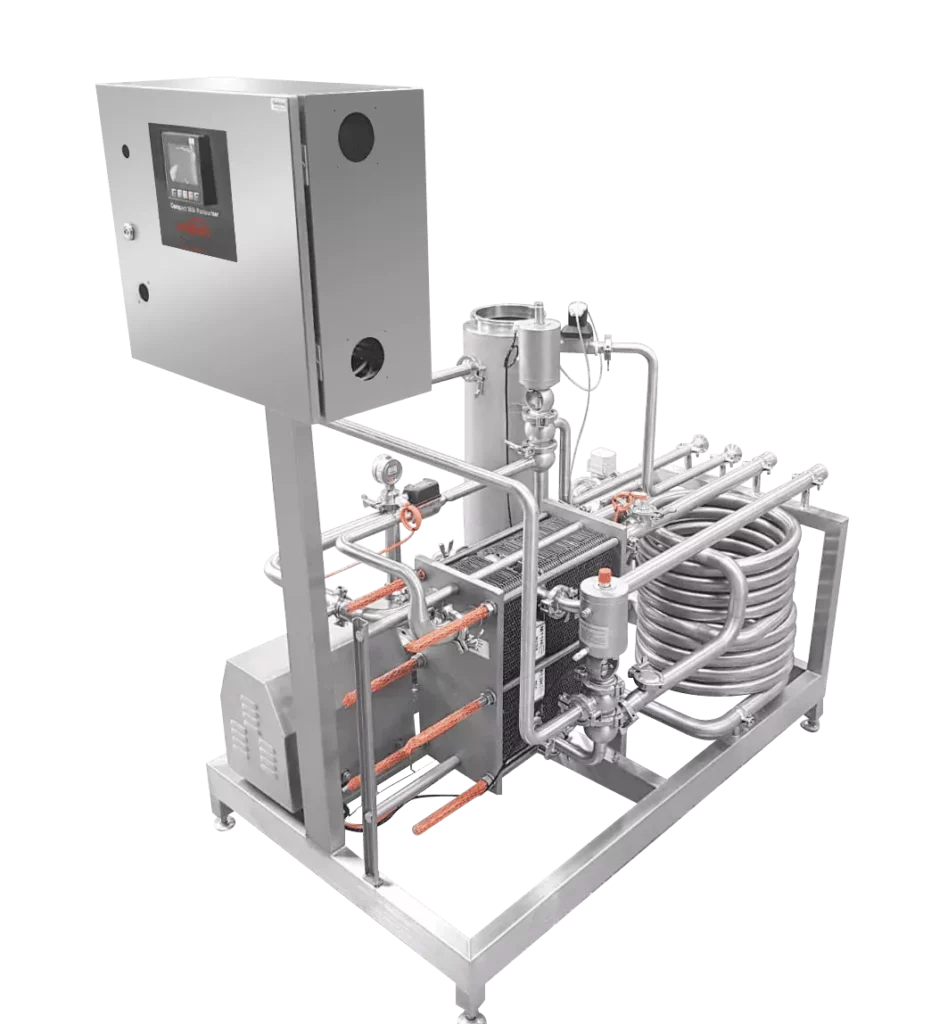

We manufacture and supply cutting-edge machinery and systems that solve real problems for our customers, specialising in pasteurisers, homogenisers, separators, heat exchangers, pumps and valves.

Unison is also revolutionising heat exchanger and tank testing with our ground-breaking Heat Exchanger Integrity Self-Testing (HEIST) and Tank Test+ systems – the world’s first fully automatic systems for integrity testing.

Our engineers are curious by nature. When we see a problem,

we think about how we can solve it. Instead of saying “that’s

impossible”, we ask “how could it be done?”

It is through this approach that we are able to consistently solve

problems for our customers in the liquid processing industry,

and it is what has powered us towards winning multiple

innovation and industry awards for our products.

Capacity: 200 L/Hr

Dimensions: 850Mm X 1,300Mm X 1,100Mm

Electric/Boiler Heater Output: – 5 Kw

Temperature: – 92°C

Fully Automatic HTST/Flash pasteuriser manufactured to suit a variety of processing requirements and products including milk, cheese, juice, honey, beer, oat milk, wine, cold brew coffee, syrups, botanical water, CBD, Flavoured drinks, kombucha and egg.