Heat exchanger integrity testing is essential in ensuring the safe and efficient operation of industrial systems and processes. Heat exchangers are used in a variety of applications, including liquid processing, power generation, chemical processing, HVAC systems, and refrigeration.

Manufacturers are all too aware that their pasteurizers, plate and tubular heat exchangers are vulnerable to cracks and other defects during their lifespan. These defects can and do cause severe contamination leading to health problems for consumers, reputational damage, and costly product recalls.

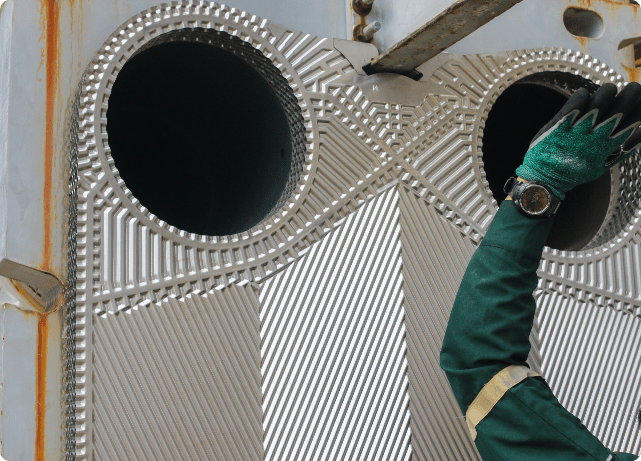

Heat exchanger integrity testing helps to identify and diagnose any issues with the heat exchanger, such as leaks, corrosion, fouling, or damage to the tubes or shell. By performing regular tests, our engineers can quickly and accurately identify any problems and make repairs or replacements before they result in more serious consequences.

Detecting these defects is necessary, but usually requires the equipment to be completely dismantled, causing downtime and loss of production at a significant cost to the business.

Our ground-breaking solutions allow companies to test their key heat exchangers quickly and effectively, with cutting-edge technology that reduces the risk of product contamination and costly recalls.

The integrated HEIST system automatically tests pasteurizers, plate and tubular heat exchangers daily for cracks or other defects, with minimum downtime and maximum accuracy. HEIST is the first system of its kind in the world – a patented, innovative, and cost-effective system that puts control of integrity testing in the hands of manufacturers. For Pasteurizers HEIST can also carry out an automatic holding time verification and diversion valve check daily.

Like HEIST, but without the automation. Pastest+ provides the same level of protection against cracked plates, but tests are run manually when desired rather than automatically at the start of each day. Validated by Campden BRI, the UK’s leading independent food and drink research organisation, Pastest+ is a non-destructive integrity and holding time test system for pasteurizers, plate and tubular heat exchangers.