Pastest+ is a non-destructive integrity test and holding time verification system for pasteurizers, plate and tubular heat exchangers.

Developed & Patented by Unison & Validated by Campden BRI, the UK’s leading independent food and drink research organisation, Pastest+ is transforming process equipment testing worldwide, resulting in substantial cost and time savings.

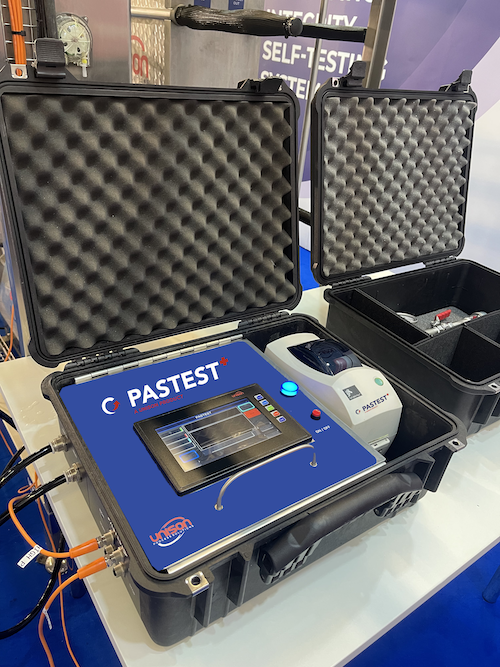

Unison’s service engineers run a test on your plate or tubular heat exchanger using the Pastest+ app and system. Our specially designed system allows us to do this without dismantling any plates and using only process water.

Capable of detecting small cracks to an accuracy of 50μs, Pastest+ technology detects pressure increases in a closed volume of the plate heat exchanger. If a crack is detected, this will be shown on the Pastest+ app, and a further inspection of the plate pack will be required.

Following the test, a QR code is generated and printed on a label which is attached to the heat exchanger. Using this QR code, you can easily view the automatically generated test result details, which prevents any operator manipulation of the final results. No more handwritten results.

The Pastest+ app automatically sends all of your results to your designated email, providing personalised access to your equipment test data. At the same time, it also saves a complete service history of all your PHEs within the app.

Pastest+ versus Other Testing Technologies

Our mission is simple: we want to reduce your downtime, save on your costs, and protect the environment, by delivering innovative, cost-effective solutions to your everyday problems.