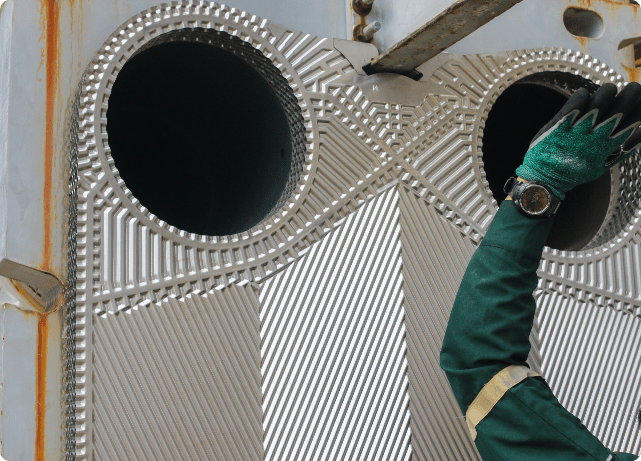

Heat Exchanger Servicing and Refurbishment

Specialists in service and repair of all makes and models of Heat Exchangers for the Dairy, Food, Beverage, Chemical and Pharmaceutical process industries.

For our heat exchanger customers in Ireland, we offer a 24/7 rapid-response service, with a well-refined capability to react quickly to the service needs of your company. Unison’s team of highly skilled service engineers carry out routine maintenance, refurbishment and emergency repairs of all makes and models of heat exchangers, including API, Arsopi, Alfa Laval, APV, GEA, Fischer, Sondex, Schmidt, Reheat, Stork, Swep, Chester Jensen, Vicarb, Tranter, Swed, Sondex, Sunflo, UK Heat Exchangers, Junkers, Pasilac and many others.

Importance of Servicing

Regular servicing is essential in minimising expensive downtime as a result of breakdown and ensuring machinery is performing effectively and safely at all times. But if a breakdown does happen we respond quickly, and target resolution of the problem on the first visit 24/7, 365 days a year. Our expert repair and inspection service team are consistently thorough, quick and professional.

Heat Exchanger Servicing and Refurbishment with Unison as your chosen partner

In Ireland, we support several different partner models that have one thing in common – we make it easy to work with us, grow your business and keep your customers uniquely happy.

From one off emergency repairs to maintenance support contracts for, Unison Process Solutions are the preferred Heat Exchanger service partner. The majority of spare parts are held at our facility in Limerick, which enables us to offer a rapid breakdown service which includes: De-gasketing, Re-gasketing, Acid cleaning, Integrity Testing ,Channel deformation, Pressure testing. We also carry a large range of Heat Exchanger Spares including: Plates , Gaskets, Port Rings, Tension Bars, Splitter Plates, Connection Plates to name but a few.

Plate packs can be delivered directly to our Service Centre or our Service Crew can go to site remove your existing plates, test their integrity and fully refurbish them so they are ready to use again. During any plate heat exchanger service for your company, Unison will thoroughly examine all plates making sure any sealing problems or deformities are corrected.

Speak to us to find out more about our automatic and engineer-led testing solutions