At Unison, we specialise in non-destructive plate and tubular heat exchanger and tank integrity testing along with holding time verification. Our innovative solutions enable your company to test key heat exchangers and tanks quickly and effectively, by utilising cutting-edge technology to reduce the risk of product contamination and costly recalls.

Choose to reduce your risk of product contamination. Choose less downtime, less testing costs, less stress, increased productivity and simpler production management. Unison’s range of integrity tests can help.

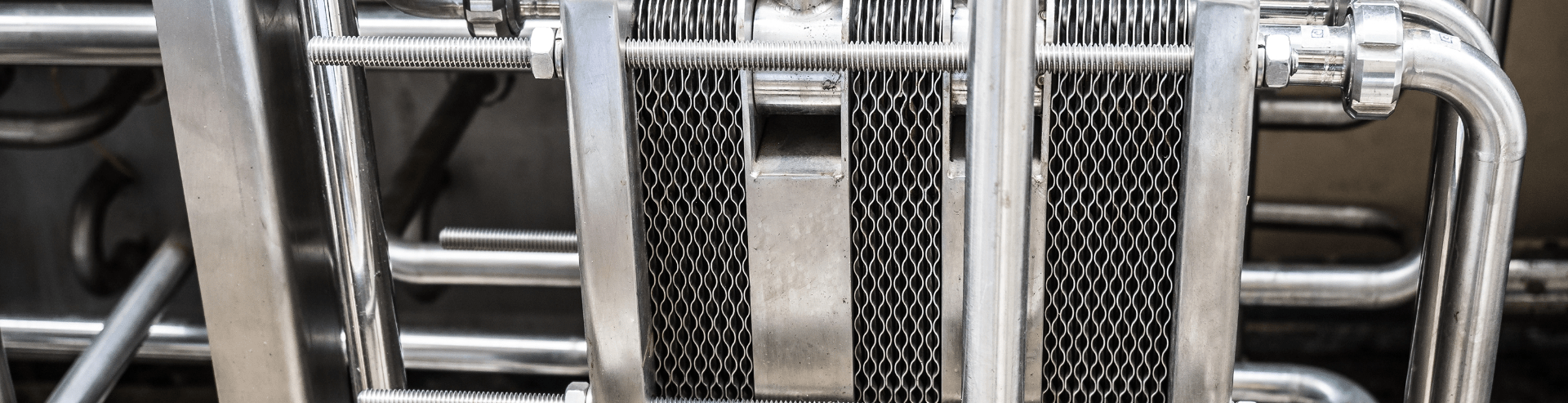

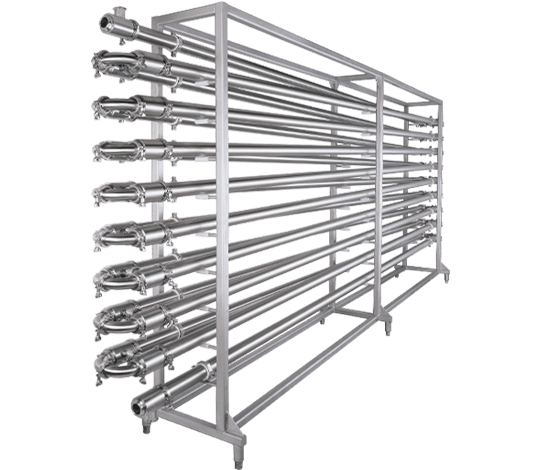

Pasteurizers, plate and tubular heat exchangers are vulnerable to cracks and other defects during their lifespan, leading to severe contamination. Our innovative, patented solutions can help prevent this from occurring.

Learn More

Jacketed tanks are notoriously prone to failure, which can result in your product being exposed to harmful liquids or gasses that can cause severe product contamination. TankTest+ our patented solution is the world’s first automatic system for testing jacketed tanks.

Learn More

Holding time verification is a method of testing used to ensure your pasteurizer is holding your product at the correct temperature for the correct duration. Our specially designed Pastest+ system allows us to verify your holding time using only process water.

Learn More

Calibrating your instruments correctly will ensure your production is consistent, accurate and of the highest quality. Even the slightest variation can result in product loss, downtime or even product recall. Our experienced calibration team can calibrate your instrumentation on or off site, quickly, accurately and at a competitive price.

Learn MoreThe integrated HEIST system automatically tests pasteurizers, plate and tubular heat exchangers daily for cracks or other defects, with minimum downtime and maximum accuracy. HEIST is the first system of its kind in the world – a patented, innovative, and cost-effective system that puts control of integrity testing in the hands of manufacturers. For Pasteurizers HEIST can also carry out an automatic holding time verification and diversion valve check daily.

Like HEIST, but without the automation. Pastest+ provides the same level of protection against cracked plates, but tests are run manually when desired rather than automatically at the start of each day. Validated by Campden BRI, the UK’s leading independent food and drink research organisation, Pastest+ is a non-destructive integrity and holding time test system for pasteurizers, plate and tubular heat exchangers.

Rather than testing once a year and waiting until signs of contamination are seen before another test is carried out, our TankTest+ system enables users to do an automatic internal and external check for cracks and defects daily (or whenever the tank is full). Following the test, the result will be sent via email or text to a designated recipient. It can also be integrated with your automation system/Scada.

Our mission is simple: we want to reduce your downtime, save on your costs, and protect the environment, by delivering innovative, cost-effective solutions to your everyday problems. Our products do not rely on outdated integrity and holding tube testing methods – we have developed a better way. Unison empowers your company to take back control, enabling quick and effective testing.